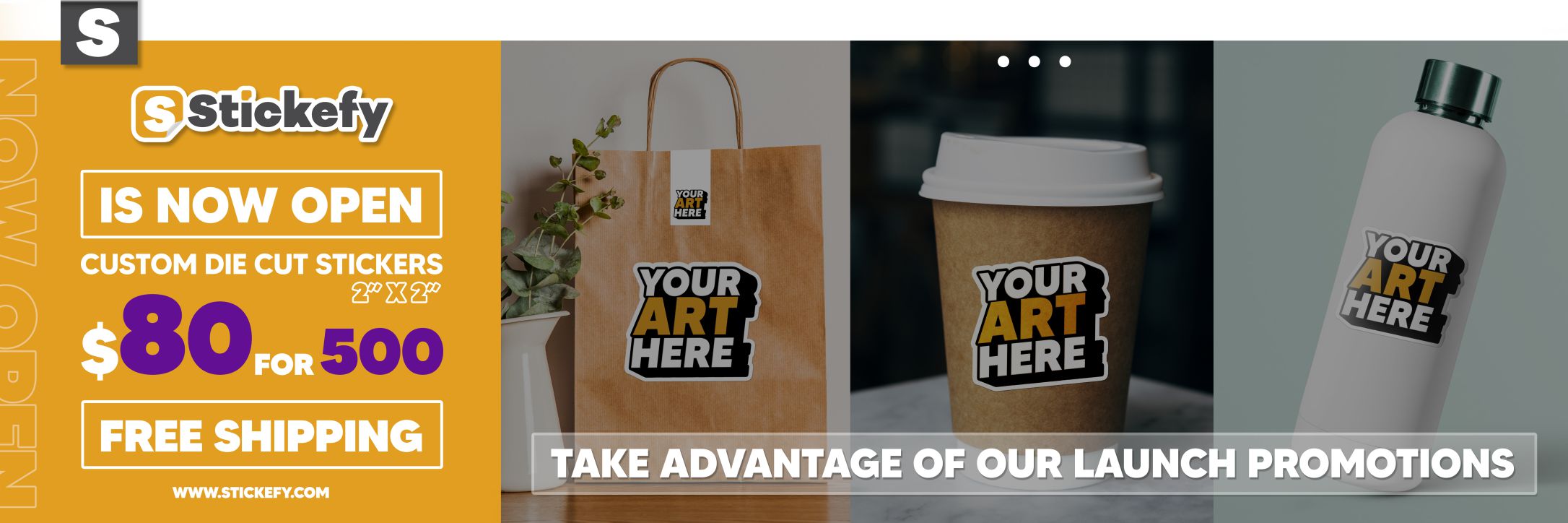

Free US Shipping

Enjoy free shipping over $50 Click here to customize

Secure Payment

Rest Easy Knowing Your Information Is Fortified by Our Ironclad Payment Portal

Lightning Production

Get Ready to Speed Ahead! Your Order Can Ship in as Little as 7 Days.

Quality Service

Our dedicated team is poised and eager to assist you through every step of your order!

Customize now:

Let customers speak for us

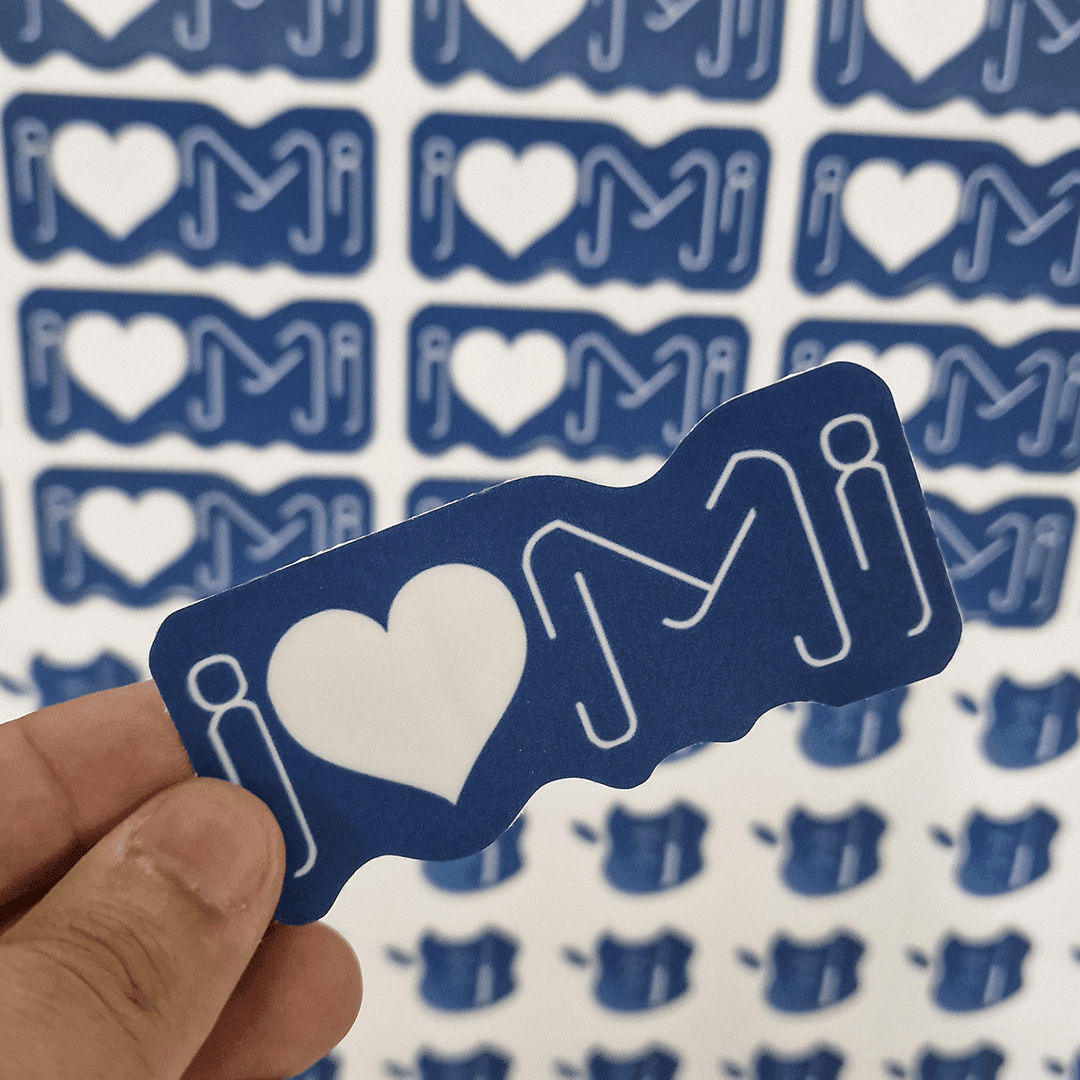

from 53 reviewsGreat price, friendly service. Will order as long as the cost stays the same.

Awesome Sticker ! Exactky What I ordered ! Gave me a few Extra ! Will order again !

Great quality timely shipping.

I Am Trilled With The Great Quality & The Way My Stickers You Produced Catch The Eye & Stand Out ! #Partyon ! #235 ! #AllTheWayLive !

Alexander C.

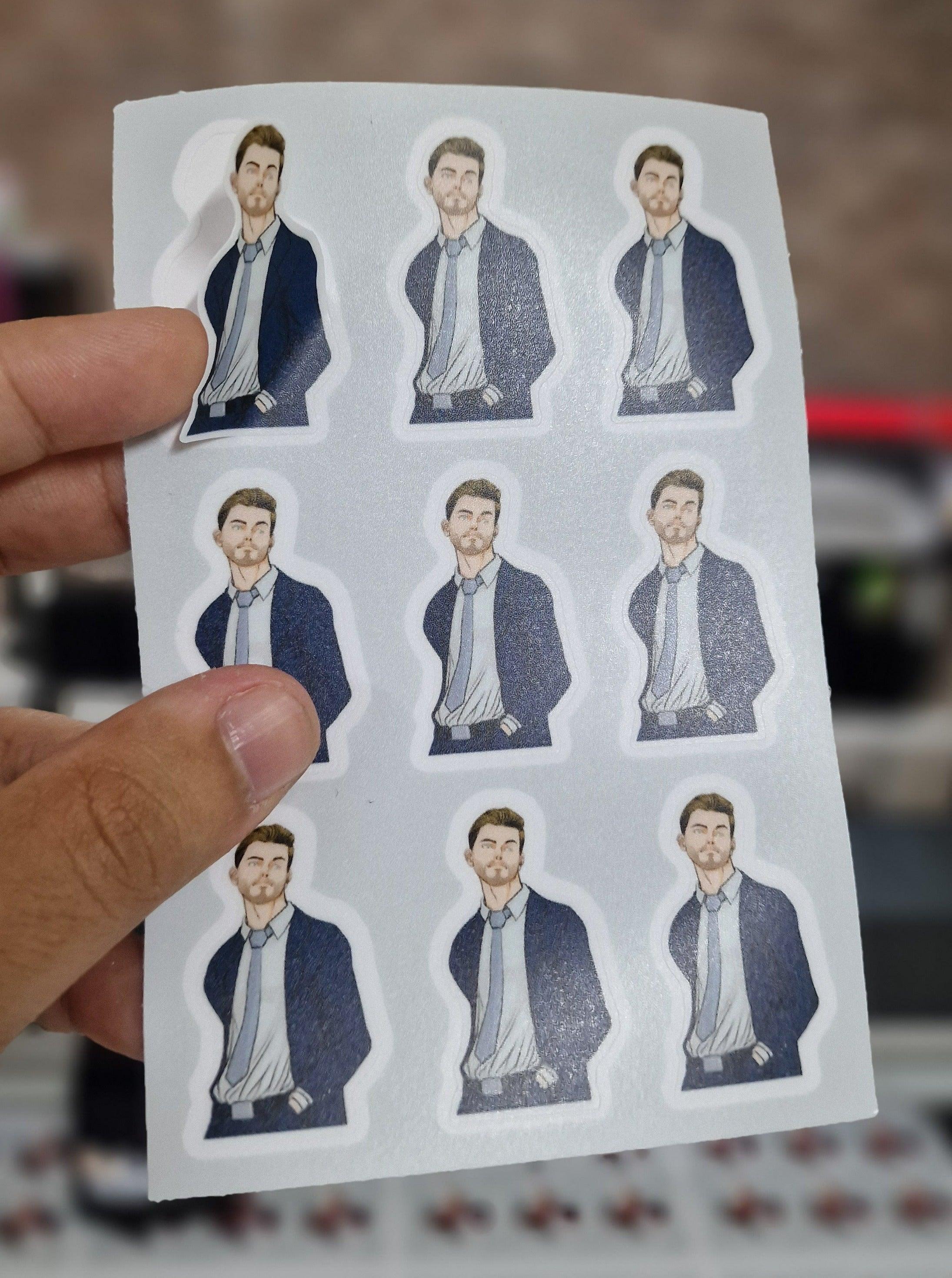

Well done. Love the quality and the clarity of it. It’s absolutely amazing. Thank you!

The colors turned out great and the quality is so good. These aren't flimsy at all. Well packaged and fast shipping, too.

These stickers came out perfect. No other words than I’ll be placing another order when I need more.

Good work, great quality sticker! Super friendly people and open to doing collab on IG!

The quality and material exceeded my expectations! Thank you!

I had a vision kin my mind and they nailed it i highly recommend this company after dealing with a lot of headaches with others

What a purchase! Stickers came out perfect in everyday & customer service reps help you out step by step, proof by proof, and make rhe process that much easier & better. Thank you Stickefy, can't wait to show our tournament participants! This One's For You BG#11! 💪🏽🥎🚒🔥🤙🏽

So exited about my new sticker line! Great quality! Look forward to ordering more!

Love you guys. Such a blessing and monster pricing. I don’t have to shop for stickers anywhere else.

The Stickefy Special

Great Quality